Complete Brake Repair Services

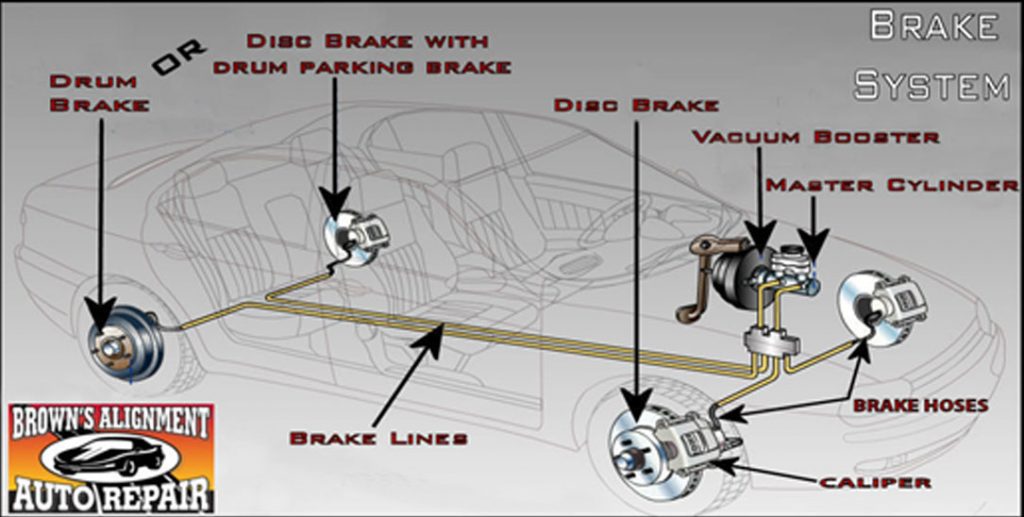

At Brown’s Alignment, Brake, and Auto Repair, our technicians have the equipment and expertise to diagnose and repair your vehicle’s brake system. We replace pads, shoes, rotors, and drums. Additionally, we are fully equipped to service the hydraulic system, including calipers, wheel cylinders, hydraulic hoses, metal lines, master cylinder, and brake booster for most cars and light trucks.

Brake Pad

Disc brake pads are the part of a vehicle’s braking system that applies friction against the brake rotor to slow down or stop the vehicle when the brake pedal is pressed. Pads are typically made of materials such as semi-metallic compounds, ceramics, or organic materials, and are mounted within the brake caliper. As the brake pads make contact with the spinning rotor they create friction, converting energy into heat. This friction is what slows down the vehicle. Properly functioning brake pads are crucial for safe and effective braking. They require regular inspection and replacement as they wear down over time.

At Brown’s Alignment, we offer both aftermarket and original equipment pads produced by the vehicle manufacturer. Aftermarket products claim additional benefits such as being longer lasting, quieter, low dust etc. However, there is often a trade off to achieve these proclaimed benefits. For example, extended life ceramic pads are often manufactured from harder materials which can result in increased rotor wear.

Brake Rotor

A brake rotor, also called a brake disc, is a circular metal component attached to a vehicle’s wheel hub. When you press the brake pedal, brake pads clamp onto the rotor’s surface, creating friction that slows down or stops the vehicle.

Today’s trends in auto manufacturing have made rotor replacement more common. Manufacturers are producing thinner rotors to reduce vehicle weight, while brake pad composition has shifted to harder, longer-lasting materials. As rotors wear down, their ability to absorb and dissipate braking heat decreases, often leading to warped rotors with brake pulsation and steering wobble. Alternatively, during brake repair, rotors can be turned or resurfaced using a brake lathe to provide a fresh, flat surface by shaving off metal. However, if rotors fall below minimum thickness, replacement is recommended, as thin rotors are more prone to overheating and warping.

Brake Master Cylinder

The brake master cylinder powers your vehicle’s hydraulic system and distributes hydraulic brake fluid to all four wheels, receiving pressure from the booster. Most master cylinders have two circuits: one for the front wheels and one for the back wheels. This design ensures that if there’s a leak in one section (e.g., the rear brakes), the other section (the front brakes) will still function. When a leak occurs, the brake pedal sinks lower to the floor. Complete failure of the master cylinder can result in total brake loss.

Routine brake fluid flushing is recommended every 2 years. Brake fluid is hygroscopic, meaning that it absorbs moisture over time. When heated during normal brake use, this excess water will boil into steam. Steam compresses more than water or brake fluid, causing the brake pedal to sink further than usual. Initially, the brake pedal may feel fine, but as you drive and the brakes heat up, too much moisture in the fluid may cause the pedal may sink lower or feel mushy.

Brake Booster

Brake Calipers

A brake caliper is a component of a vehicle’s braking system that plays a crucial role in applying pressure to the brake pads. They house the brake pads and sit on top of the brake rotor. When the driver presses the brake pedal, hydraulic pressure forces the pistons inside the caliper to push the brake pads against the rotor, creating friction and stopping the vehicle.

Brake Lines & Hoses

Metal brake lines transport brake fluid from the master cylinder to each wheel. These lines connect to wheel cylinders in the drum brake system. In disc brake setups, a rubber hose connects the metal line to the caliper.

Drum Brake System

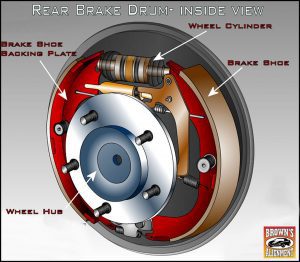

In a drum brake system, when the brake pedal is pressed, hydraulic pressure is applied to the brake shoes. The brake shoes are located inside a drum attached to the wheel hub. The hydraulic pressure causes the brake shoes to press against the inner surface of the drum, creating friction and slowing down the rotation of the wheel.

The brake shoes have friction material lining their inner surface, which helps to create the necessary friction for braking. As the brake shoes press against the drum, the friction between them converts the energy of the rotating wheel into heat energy, slowing down the vehicle.

Drum brakes use mechanisms such as springs and adjusters to ensure proper operation and to compensate for wear over time. When the brake pedal is released, springs pull the brake shoes away from the drum, allowing the wheel to rotate freely again.

While drum brakes are still used in some vehicles, they are less common than disc brakes due to their lower efficiency and performance, especially during heavy braking or in wet conditions.